Precision EDM Electrodes Built for Performance

Precision EDM Services for Complex Parts

When precision matters, trust the pioneers in EDM machining.

With over 65 years of experience, Saturn Industries is one of the nation’s premier manufacturers of high-performance EDM electrodes. We supply graphite, metallic, and specialty electrodes to companies across aerospace, medical, automotive, and industrial sectors—designed for accuracy, durability, and consistency.

Our focus is on providing the tooling you need to keep your machines running at peak performance. From job shops to contract manufacturers, we’re here to supply the highest quality electrodes so you can deliver the best results to your clients.

Why Choose Saturn Industries?

We’ve been EDM Specialists Since 1959

Custom Made to Print – Built to your specs for any EDM application

Fast Turnaround – Rapid prototyping and production runs

What We Offer

Graphite EDM Electrodes

We offer a full range of precision graphite electrodes, crafted from top industry grades like POCO and others.

Benefits include:

- Exceptional wear resistance (<1% wear in high-amp applications)

- Superior surface finishes at higher machining speeds

- Reduced total EDM time and lower production costs

- Custom shapes and sizes: airfoil, seal slot, vane, rods, tubes, and blanks

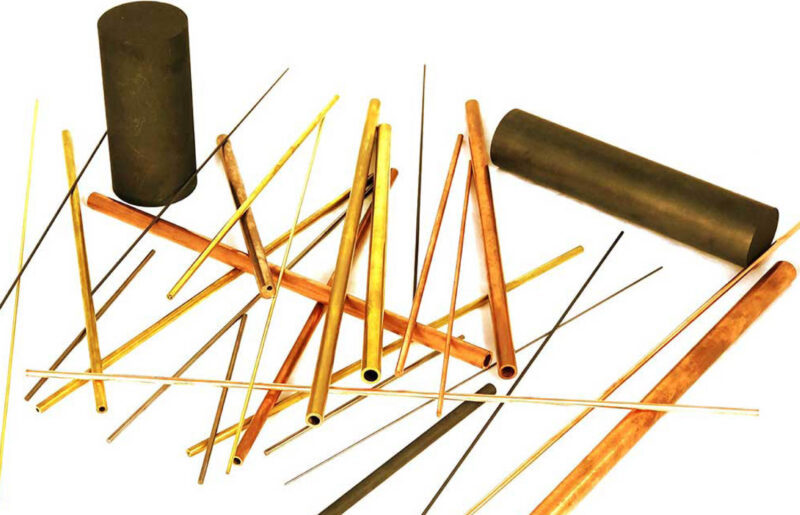

Metallic EDM Electrodes

We manufacture metallic electrodes from a wide range of materials:

- Copper

- Copper Tungsten

- Brass & Tellurium Copper

- Tungsten Carbide & Pure Tungsten

Custom fabrication available for complex geometries and high-precision specs.

Tapping Electrodes

Saturn is a recognized leader in tapping electrode fabrication. All electrodes are manufactured to ±.002 pitch diameter tolerance and include features such as timed flats and customizable thread forms for repeatable placement.

- Standard and orbiting

- Materials: POCO EDM 3/C3, Brass, Copper, Copper Tungsten

- Sizes: Inch, metric, NPT – in 3” and 6” lengths

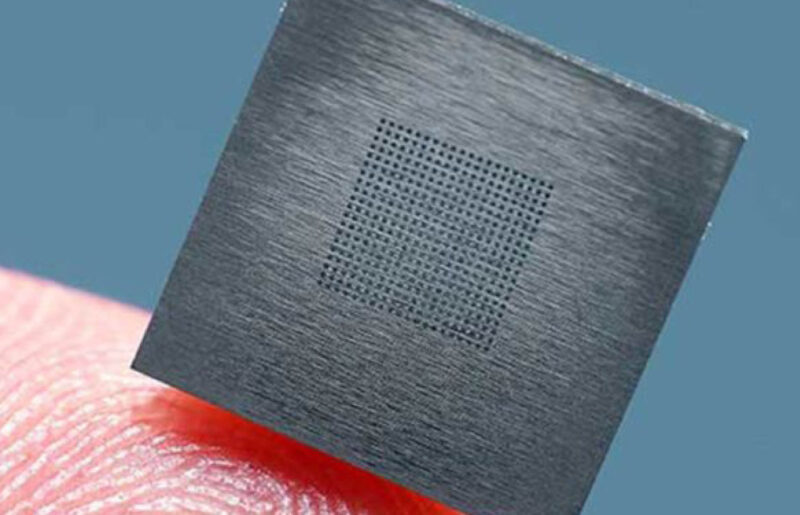

Small Hole EDM Electrodes (“Hole Poppers”)

We supply both single- and multi-channel electrodes for small hole drilling:

- Materials: Brass, Copper, Copper Tungsten, Tungsten Carbide

- Diameters from .003″ (single) to .0157″ (multi)

- Available as tubes, roto tubes, and solid rods

- OD tolerances as tight as +/-.00002″

Quality Control

Since day one, we’ve invested in high-precision inspection equipment to ensure every EDM part meets the strictest quality standards. This commitment to accuracy has fueled our growth and built lasting customer trust.