CNC Machining Services – CNC Turning

Saturn Industries Inc. is today’s leader in CNC Turning Part Manufacturing. Our knowledgeable staff and state of the art machinery makes our services superior in our industry. We are equipped with 7 Axis live tooling and Swiss CNC turning centers complete with part catchers and bar feeders. We offer Prototyping services to large quantity production runs. We offer lathe turning machining services for the medical, aerospace, automotive, electronic and EDM industries. Saturn Industries also offers CNC Milling and CNC Centerless Grinding services.

CNC Turning at Saturn Industries

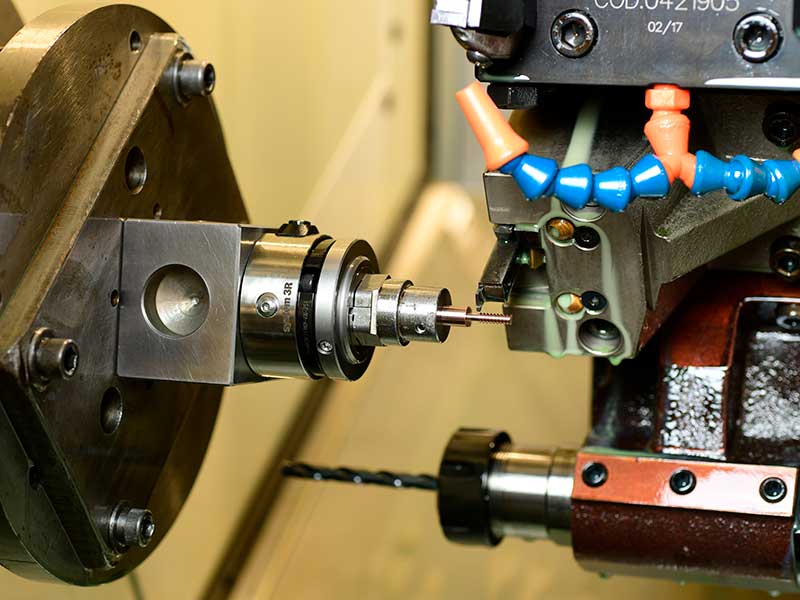

A component can be created in the finest detail and to rigid of designs using a Computer Numerical Control (CNC) lathe, with precise tolerances and in a variety of shapes. The turning lathe secures and rotates the chosen material, while a single point cutting tool shapes the material, resulting in the desired product. The lathe is controlled by the computer program; ensuring exact components are produced, and reproduced. At Saturn Industries, we pride ourselves on being the leaders in the latest CNC Turning Technology and Processes, and on our ability to create the parts our customers demand cost-effectively and on-time.

Difference Between CNC Milling and Turning

CNC Milling and CNC Turning allow users to create patterns and add detail to metals that are impossible to do by hand. CNC Milling uses commands, codes programmed into the computer and set to run. The mill then drills and turns along axes to cut materials to dimensions entered into the computer. Computer programming allows machines to make precise cuts, users can manually override the CNC Machines to slow or speed up the process.

In contrast, CNC Turning uses computer-controlled machines to create a different final product. The process uses a single-point cutting tool that inserts parallel to the material to cut. The material is rotated at changing speeds and the tool cutting traverses to create cylindrical cuts with exact measurements. It is used to create circular or tubular shares from larger material pieces. It is an automated process and speeds can be adjustments for greater accuracy rather than turning a lathe by hand.

If you’re not sure if your part should be best produced by Turning or Milling, call our experts, we’ll go over the project and recommend the best process for your project.

Materials for CNC Turning

This machining process can handle most rigid materials including most metals: Aluminum, Stainless Steel, Copper, Steel, Brass, Titanium, Sterling Silver, Bronze, and graphite. See our complete list of materials below.

Let Saturn Industries Quote Your Project

We can quote your job using conventional CAD files, fill out our simple form and we will contact you with a competitive quote. Saturn Industries, is constantly striving to improve and optimize our processes and maximize customer convenience. Our customers range from inventors to businesses to government agencies. We are focused on quality and customer service.

CNC Turning Machining Processes Include:

Boring

Counter Boring

Cutting

Counter Sinking

Drilling

Facing

Parting

Pocketing

Profiling

Internal Forming

Knurling

Contour Turning

Taper Turning

Form Turning

Straight Turning

Internal Threading

External Threading

Reaming

Tapping

Thread Milling

Materials

Aluminum

Alloy Steels

Copper Graphite

Stainless Steel

Brass

Copper

Bronze Alloys

Nylon

Steel

Acetal

Carbon Steel

Iron

Polycarbonate

Acrylic

Teflon

Titanium

ABS

Molybdenum

Stellite

Tin

Titanium

Tungsten

Copper Tungsten

Silver Tungsten

Zinc

Graphite

Sterling Silver

Peek

Plastics

Polyethylene

PVDF

Equipment

Machinery

CNC Turning Lathes

Tool Room Lathes

Swiss Turning Lathes

Machine Fixturing:

Three/Four Jaw Chucks

General Fixturing and Tooling

Capabilities

Computer Controlled Lathes

CNC and Conventional Turning/Milling

CAD/CAM/SolidWorks/Esprit Programming/Designing Services

3D Part Reverse Imagining/ Engineering

High Pressure Coolant Systems TSC/HSM

Variable Spindle Speeds

Dust Collection

High Speed Machining

Machine Axis:

7

Part Diameter

Max 11.4” Dia

Part Length:

Max 22” L

Applications

Shift Knobs

Motorcycle Parts

Automotive Parts

Toy Parts

Knobs

Machined Components

Pins

Standoffs

Electrodes

Fittings

Bushings

Rod Threading

Spacers

Valves

Shafts

Turbine Components

Engine Components

Hubs

Fasteners

Spindles

Sockets

Hydraulic Parts

Turbo Machinery Parts

Construction Equipment

Industries

Automotive

Aerospace

Military/Defense

Construction

EDM

Mining

Marine

Industrial

Medical

Production Capabilities:

Prototyping

1 Part Minimum

Low Quantity Runs

Large Quantity Runs

High Production Volume

Large Scale Production

Quoting/Delivery:

Quotes based on each job request

Quick Quoting/Turnarounds

Rush Service Available upon request

Additional Turning Capabilities:

Centerless Grinding

Certifications:

ISO 9001:2015